Corvette Parts And Accessories

Misconceptions About Hydro-Dipped Carbon Fiber vs. Real Carbon Fiber

There are several misconceptions about hydro dipped carbon fiber vs. real carbon fiber in the world of aftermarket Corvette accessories. Carbon fiber is a popular choice for enhancing both the aesthetic appeal and performance of vehicles. However, there is a significant debate between real carbon fiber and hydro-dipped carbon fiber, also known as hydro dipping. At Classic Trim Customs, Inc., we specialize in providing high quality hydro dipped Corvette accessories. Today, we aim to clarify some misconceptions surrounding these two materials and highlight the advantages of hydro-dipping for your Corvette.

Misconception 1: Real Carbon Fiber is Always Superior

Reality: While real carbon fiber is renowned for its strength and lightweight properties, it is not always the superior choice for every application. One of the biggest drawbacks of real carbon fiber is its susceptibility to environmental damage. Over time, real carbon fiber can yellow and crack, especially when exposed to UV light. This deterioration can diminish the aesthetic appeal and structural integrity of the material.

Misconception 2: Hydro-Dipped Carbon Fiber is Just a Cheap Imitation

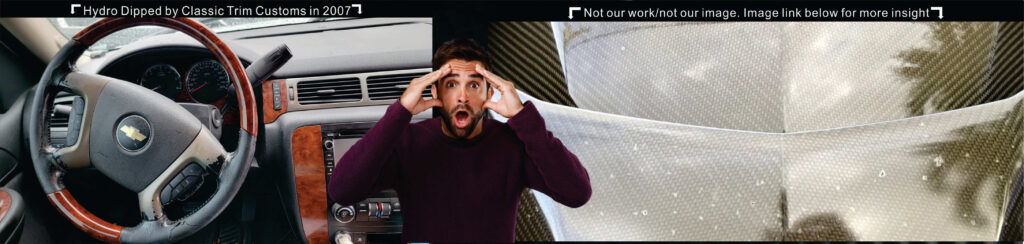

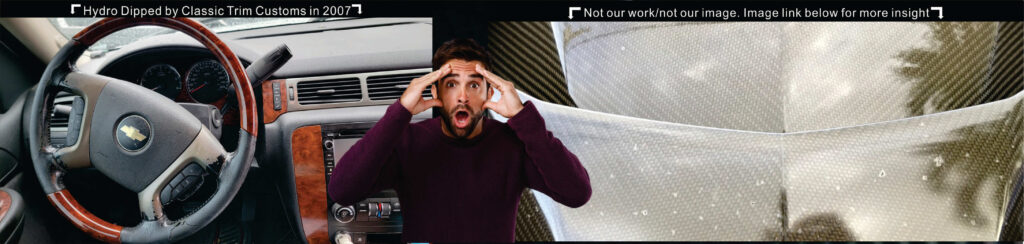

Reality: Hydro-dipped carbon fiber is often unfairly labeled as a cheap imitation of the real thing. However, hydro dipping is a sophisticated process that involves applying a water-transferable film with a carbon fiber pattern onto a surface, followed by a clear coat for protection. When done correctly with quality materials, hydro-dipped carbon fiber can be incredibly durable and visually appealing.

Misconception 3: Hydro-Dipped Finishes Don’t Last

Reality: This myth likely stems from experiences with low-quality hydro dipping. At Classic Trim Customs, Inc., we use only UV-stable, high-quality paints and clear coats that ensure the finish does not dull over time. Unlike real carbon fiber, which can yellow and crack, a properly applied hydro-dipped finish can outlast the finish of real carbon fiber, maintaining its appearance and protection for years to come.

Misconception 4: Real Carbon Fiber is Maintenance-Free

Reality: Maintaining real carbon fiber requires diligence. It needs regular cleaning and special care to prevent yellowing and cracking. On the other hand, hydro-dipped carbon fiber is relatively low-maintenance. The protective clear coat used in hydro dipping is designed to withstand the elements, making it easier to keep looking new with minimal effort.

Misconception 5: Hydro-Dipped Carbon Fiber Lacks Strength

Reality: It’s important to understand that hydro-dipping is a surface finish, not a structural material. When we hydro dip parts at Classic Trim Customs, Inc., we apply the finish to a base material that is already strong and durable, such as high-quality plastics or metals. The hydro-dipped finish provides the desired carbon fiber look without compromising the part’s structural integrity.

The Benefits of Hydro-Dipped Carbon Fiber

- Cost-Effective: Hydro-dipped carbon fiber is generally more affordable than real carbon fiber. This allows enthusiasts to achieve the high-end look of carbon fiber without breaking the bank.

- Customizable: The hydro-dipping process offers a level of customization that real carbon fiber cannot match. You can choose from various patterns and colors, allowing for unique and personalized designs.

- Durability: As mentioned, a quality hydro-dipped finish, like the ones we provide, can withstand environmental challenges better than real carbon fiber, thanks to the protective UV-stable clear coat.

- Versatility: Hydro dipping can be applied to a wide range of materials and parts, from interior trim pieces to exterior components. This versatility makes it an excellent choice for various applications.

Choosing the Right Finish for Your Corvette

When deciding between real carbon fiber and hydro-dipped carbon fiber, consider the specific needs and goals of your project. If you are looking for a high-performance part that will be subjected to extreme conditions, real carbon fiber might be the way to go. However, if you want a durable, aesthetically pleasing finish that can withstand the elements and requires less maintenance, hydro-dipped carbon fiber is an excellent option.

At Classic Trim Customs, Inc., we are committed to providing our customers with the best quality aftermarket Corvette accessories. We ensure that our products meet the highest standards of quality and durability.

Conclusion

The debate between real carbon fiber and hydro-dipped carbon fiber is filled with misconceptions. By understanding the realities of both materials, Corvette enthusiasts can make informed decisions that best suit their needs. Hydro-dipped carbon fiber offers a cost-effective, customizable, and durable alternative to real carbon fiber, making it a valuable option for many applications.

If you’re looking to enhance your Corvette with high-quality aftermarket accessories, contact Classic Trim Customs, Inc. today. Our team of experts is here to help you choose the perfect finish for your project, ensuring your Corvette looks and performs its best for years to come.

FAQs

Q: Can hydro-dipped carbon fiber be repaired if damaged? A: Yes, assuming the part the finish was applied to is good the hydro-dipped finish can often be repaired by reapplying the hydro-dip film and clear coat.

Q: How long does the hydro-dipped finish last? A: A quality hydro-dipped finish can last years without fading or dulling.

Q: Is real carbon fiber lighter than hydro-dipped parts? A: The weight difference depends on the base material of the hydro-dipped part. Real carbon fiber is inherently lightweight, but the difference may be minimal depending on the application.

For more information and expert advice on aftermarket Corvette accessories, visit Classic Trim Customs, Inc. and let us help you transform your vehicle into a true masterpiece.

Misconceptions About Hydro-Dipped Carbon Fiber vs. Real Carbon Fiber

In the world of aftermarket Corvette accessories, carbon fiber is a popular choice for enhancing both the aesthetic appeal and performance of vehicles. However, there’s a lot of debate between real carbon fiber and hydro-dipped carbon fiber, also known as hydro dipping. At Classic Trim Customs, Inc., we specialize in providing high-quality hydro-dipped Corvette accessories. Today, I want to clear up some common misconceptions surrounding these two materials and highlight why hydro dipping is a fantastic choice for your Corvette.

Misconception 1: Real Carbon Fiber is Always Superior

Reality: Sure, real carbon fiber is strong and lightweight, but it’s not always the best option. One major downside is that it can yellow and crack over time, especially when exposed to UV light. This can really take away from its look and structural integrity.

Misconception 2: Hydro-Dipped Carbon Fiber is Just a Cheap Imitation

Reality: People often think hydro-dipped carbon fiber is a low-quality knockoff. But the truth is, hydro dipping is a sophisticated process where we apply a water-transferable film with a carbon fiber pattern onto a surface, then finish it with a clear coat for protection. When done right, hydro-dipped carbon fiber is durable and looks fantastic.

Misconception 3: Hydro-Dipped Finishes Don’t Last

Reality: This myth usually comes from seeing poor-quality hydro dipping. At Classic Trim Customs, Inc., we only use UV-stable, high-quality paints and clear coats. This ensures our finishes don’t dull over time. Unlike real carbon fiber, which can yellow and crack, a well-applied hydro-dipped finish can outlast real carbon fiber, keeping its appearance and protection for years.

Misconception 4: Real Carbon Fiber is Maintenance-Free

Reality: Real carbon fiber actually needs quite a bit of care. It requires regular cleaning and special attention to prevent yellowing and cracking. On the flip side, hydro-dipped carbon fiber is much easier to maintain. The clear coat we use in hydro dipping is designed to withstand the elements, making it simple to keep looking new with minimal effort.

Misconception 5: Hydro-Dipped Carbon Fiber Lacks Strength

Reality: It’s important to understand that hydro dipping is a surface finish, not a structural material. When we hydro dip parts, we apply the finish to a base material that’s already strong and durable, like high-quality plastics or metals. The hydro-dipped finish gives you that carbon fiber look without compromising the part’s strength.

The Benefits of Hydro-Dipped Carbon Fiber

- Cost-Effective: Hydro-dipped carbon fiber is generally more affordable than real carbon fiber. This allows enthusiasts to achieve the high-end look of carbon fiber without breaking the bank.

- Customizable: The hydro-dipping process offers a level of customization that real carbon fiber cannot match. You can choose from various patterns and colors, allowing for unique and personalized designs.

- Durability: As mentioned, a quality hydro-dipped finish, like the ones we provide, can withstand environmental challenges better than real carbon fiber, thanks to the protective UV-stable clear coat.

- Versatility: Hydro dipping can be applied to a wide range of materials and parts, from interior trim pieces to exterior components. This versatility makes it an excellent choice for various applications.

Choosing the Right Finish for Your Corvette

When deciding between real carbon fiber and hydro-dipped carbon fiber, consider the specific needs and goals of your project. If you are looking for a high-performance part that will be subjected to extreme conditions, real carbon fiber might be the way to go. However, if you want a durable, aesthetically pleasing finish that can withstand the elements and requires less maintenance, hydro-dipped carbon fiber is an excellent option.

At Classic Trim Customs, Inc., we are committed to providing our customers with the best quality aftermarket Corvette accessories. We ensure that our products meet the highest standards of quality and durability.

Conclusion

The debate between real carbon fiber and hydro-dipped carbon fiber is filled with misconceptions. By understanding the realities of both materials, Corvette enthusiasts can make informed decisions that best suit their needs. Hydro-dipped carbon fiber offers a cost-effective, customizable, and durable alternative to real carbon fiber, making it a valuable option for many applications.

If you’re looking to enhance your Corvette with high-quality aftermarket accessories, contact Classic Trim Customs, Inc. today. Our team of experts is here to help you choose the perfect finish for your project, ensuring your Corvette looks and performs its best for years to come.

FAQs

Q: Can hydro-dipped carbon fiber be repaired if damaged? A: Yes, assuming the part the finish was applied to is good the hydro-dipped finish can often be repaired by reapplying the hydro-dip film and clear coat.

Q: How long does the hydro-dipped finish last? A: A quality hydro-dipped finish can last years without fading or dulling.

Q: Is real carbon fiber lighter than hydro-dipped parts? A: The weight difference depends on the base material of the hydro-dipped part. Real carbon fiber is inherently lightweight, but the difference may be minimal depending on the application.

By addressing these misconceptions, I hope to shed some light on the real benefits of hydro-dipped carbon fiber. If you’re looking for high-quality, durable, and stylish accessories for your Corvette, hydro dipping is definitely worth considering. At Classic Trim Customs, Inc., we’re here to provide you with the best options to enhance your Corvette.